In the world of B2B manufacturing, a promise of customization is only as good as the process behind it. For global partners seeking reliability without the rigidity of large-scale OEMs, transparency is key. At QINGDAO ZHONGDILUHUI MACHINERY, our strength lies in a streamlined, collaborative, and responsive process designed to turn your unique specifications into durable, functional reality.

Phase 1: Deep Dive Consultation – Understanding Your “Why”

Every successful project starts with clarity. We go beyond basic dimensions to understand the application, environment, load requirements, and workflow integration needs.

- Direct Communication Channels: Utilize WhatsApp, email, or video calls for real-time discussion.

- Requirement Analysis: We help translate operational needs into technical specifications.

- Initial Feasibility & Advice: Our team provides practical feedback on materials (steel, plastic, wood) and design for optimal durability and cost-efficiency.

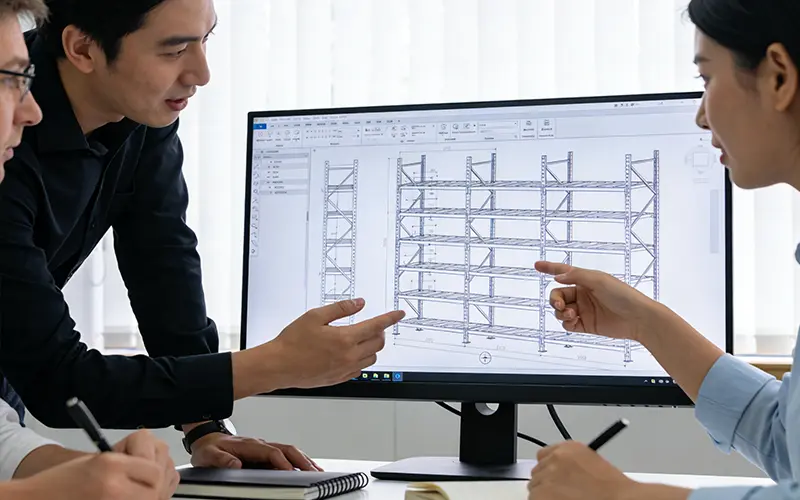

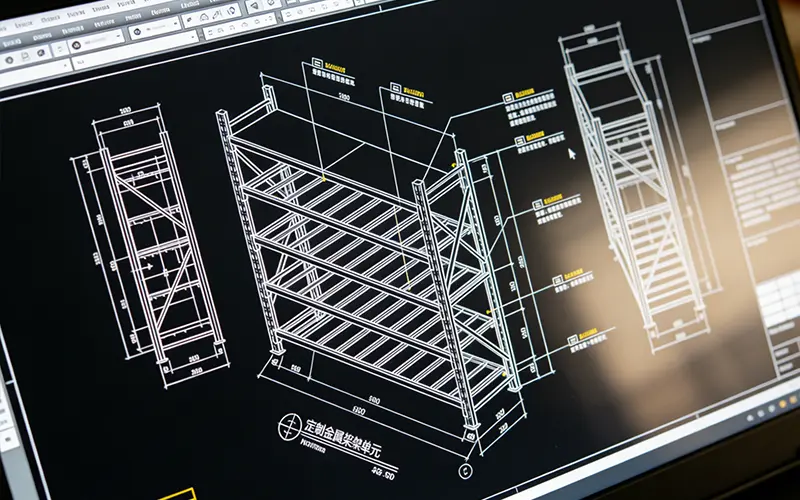

Phase 2: Co-Creation & Design Formalization

This is where your idea gets structure. We bridge the gap between concept and manufacturable design.

- Technical Drawing Generation: We create detailed 2D/3D drawings based on our discussions.

- Material Selection Guidance: We present options—from gauge thickness of steel to type of plywood or industrial plastic—balancing performance with budget.

- Design Review & Approval: We send drawings for your sign-off, ensuring every measurement and detail is confirmed before production begins. Revisions are welcomed at this stage.

Phase 3: Agile Manufacturing with Quality Interlocks

With approved drawings, our workshop springs into action. Our size allows for agility without sacrificing oversight.

- Material Procurement & Preparation: Sourced materials are inspected and cut/prepared to exact specifications.

- Fabrication & Assembly: Skilled welders, carpenters, and assemblers work on your order. Processes may include cutting, bending, welding, sanding, and assembly.

- In-Process Quality Checks: Supervisors verify critical dimensions and construction at key stages, not just at the end.

Phase 4: Finishing, Final Inspection & Preparation for Journey

The final touches ensure longevity and professional presentation.

- Surface Treatment: This may include grinding, priming, painting (powder coating options available), or applying protective sealants to wood.

- Rigorous Final Audit: The completed product is compared against the original drawings and checked for function, stability, and finish quality.

- Secure Packaging: We use robust, export-ready packaging (wooden crates, thick cardboard) to protect your goods during transit.

Phase 5: Logistics Coordination & Ongoing Support

We manage the handoff to ensure a smooth conclusion.

- Shipping Documentation: We assist with commercial invoices, packing lists, and other required documents.

- Logistics Support: We can help arrange freight or work with your chosen forwarder from the port of Qingdao.

- Post-Delivery Follow-up: We check in to ensure everything arrived as expected and address any post-assembly questions.

Why Process is Our Most Important Product

For businesses in Germany, Canada, Brazil, or the UAE, finding a partner who is both flexible and dependable is crucial. Our process is built to provide:

- Control & Visibility: You are involved and informed at every major step.

- Adaptability: We can accommodate mid-stream adjustments more readily than large factories.

- Accountability: A clear, documented process ensures we deliver on our promises.

Ready to Experience a Manufacturing Partnership Defined by Clarity and Responsiveness?

Your design deserves our precision. Let’s start a dialogue and see how our process can bring your next project to life with quality and reliability.

Contact us to begin with a design consultation. Share your sketches or ideas, and we’ll provide a preliminary assessment and quote.

Email: info@zdlhtools.com

WhatsApp: +86 15806555955

Discuss Your Project: Contact – zdlhtools.com