Every industry has its unique chaos. In a bustling automotive workshop, the cost of that chaos is measured in lost time: mechanics searching for tools, cluttered workspaces slowing repairs, and generic storage failing under heavy, greasy loads. This is where off-the-shelf products hit their limits, and true customization proves its value.

While we protect client confidentiality, this composite case study is based on real challenges and solutions we’ve engineered for partners in markets like Germany, South Africa, and the UAE. It illustrates how we translate common industry pain points into tangible, efficiency-boosting hardware.

The Client’s Challenge: Containing the Chaos

A growing auto repair business faced critical bottlenecks:

- Tool Time-Waste: Mechanics spent 15-20 minutes per job just locating and gathering tools from scattered shelves and boxes.

- Inflexible Workspace: Standard workbenches couldn’t accommodate both large engine parts and delicate electronic diagnostic equipment.

- Mobility Issues: Heavy toolboxes were difficult to move around vehicles, especially in tight bays.

- Durability Concerns: Retail-grade carts wobbled under the weight of professional pneumatic and diagnostic tools.

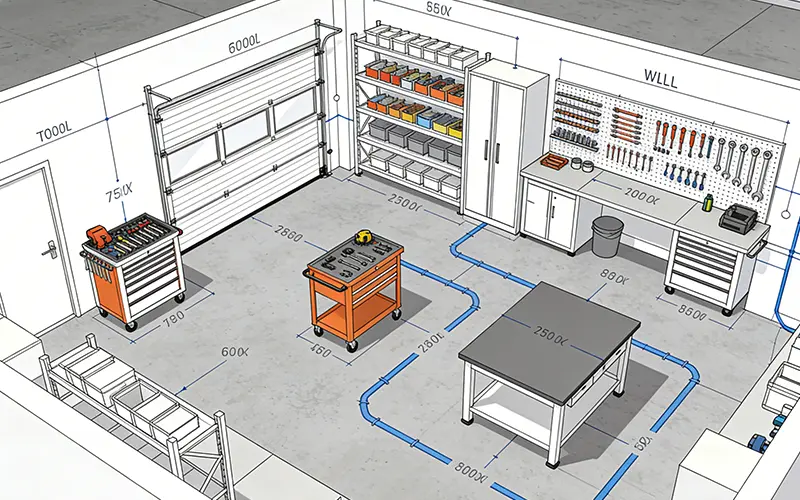

Our Tailored Solution: Designing for the Flow of Work

We collaborated to develop a three-part integrated system:

1. The Multi-Tiered, Heavy-Duty Modular Tool Cart:

- Custom Dimensions: Designed to fit snugly beside full-size SUVs and under lifted cars.

- Task-Specific Organization: Top drawer with foam cutouts for precision tools; middle shelves for power tools; bottom heavy-gauge shelf for bulky items like impact guns.

- Enhanced Mobility: Large, rubber-locked casters (two swivel, two fixed) for easy maneuvering on concrete, with a central foot brake.

- Integrated Power: A built-in power strip with cable management for charging cordless tools and running diagnostics.

2. The Hybrid Duty Workbench:

- Dual-Zone Surface: One end featured a thick, durable steel plate for hammering and heavy part assembly. The other end had a smooth, sealed wooden surface for clean electronic work.

- Built-In Utility: Included overhead LED lighting, a backsplash with hooks for frequently used tools, and lower cabinets for bulky fluid containers.

3. Dedicated Wall-Mounted Shelving System:

- Adaptable Storage: Custom-sized bays for storing tires, exhaust systems, and plastic bins for common replacement parts (filters, bulbs).

- Clear Labeling Zones: Incorporated metal tag holders on each shelf for easy inventory management.

The Documented Outcome: Measurable Gains

Post-implementation feedback confirmed significant improvements:

- Tool Retrieval Time Reduced by ~70%, saving an estimated 45 minutes per mechanic per day.

- Workspace Utilization Improved, allowing an additional service bay to be configured in the same area.

- Technician Satisfaction Increased due to reduced frustration and a more professional environment.

- Equipment Longevity: The robust construction showed no signs of wear after months of heavy use, justifying the investment.

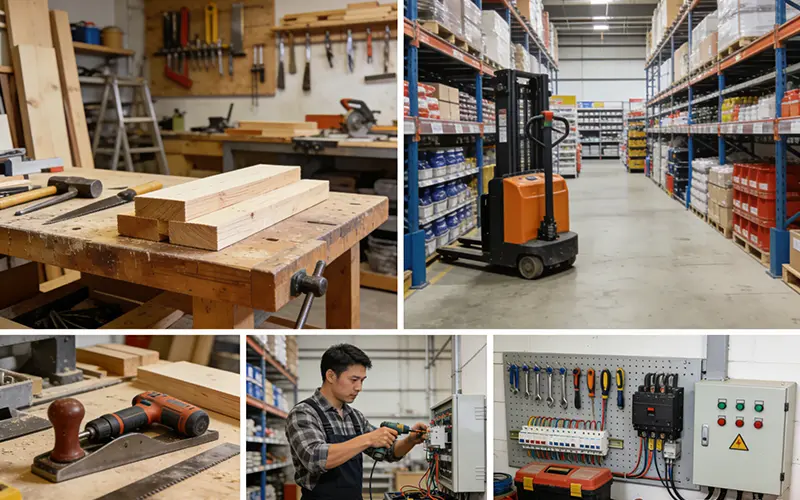

The Customization Mindset: Applicable to Your Sector

Whether you operate a woodworking shop needing custom dollies for sheet goods, a retail warehouse requiring unique shelving for irregular products, or an MRO facility (Maintenance, Repair, and Operations) with specific tooling needs, the principle is the same.

- We analyze your workflow.

- We design around your assets.

- We build for your daily demands.

Ready to Transform Your Workspace Efficiency?

Don’t let inefficient storage and furniture hold your team’s potential back. If you see your own challenges reflected in this case study, imagine the gains a tailored solution could bring to your operation.

Contact us for a free, no-obligation workflow analysis. Describe your space and your biggest daily frustration. Let’s build the solution that helps your team work smarter, not harder.

Email: info@zdlhtools.com

WhatsApp: +86 15806555955

Tell us about your workspace: Contact – zdlhtools.com