Is your current storage setup a source of daily friction? Do your employees waste time searching for tools, navigating cluttered aisles, or dealing with inefficient use of valuable floor space? Off-the-shelf shelving often promises a quick fix but delivers a long-term constraint. The true key to operational excellence lies not on the shelf, but in the blueprint.

At QINGDAO ZHONGDILUHUI MACHINERY, we believe storage should be an active catalyst for efficiency, not a passive receptacle. Custom storage solutions are engineered not just to hold your items, but to optimize your entire workflow, from receiving to shipping, empowering your team and maximizing your ROI.

The Hidden Costs of “One-Size-Fits-All” Storage

Standard shelving units come with fixed dimensions and configurations. This inflexibility leads to:

- Wasted Vertical & Horizontal Space: Gaps above shelves or narrow, unused aisles represent lost revenue per square foot/meter.

- Inefficient Workflows: Tools, parts, or materials are not stored in the optimal sequence for your production or picking process.

- Safety Hazards: Overloaded standard shelves, improper item placement, and cluttered walkways increase accident risks.

- Reduced Productivity: Employees spend more time searching and retrieving than doing value-adding work.

How Customization Becomes Your Competitive Advantage

Our approach is collaborative and solution-driven. We start by understanding your unique challenges, inventory profile, and operational goals.

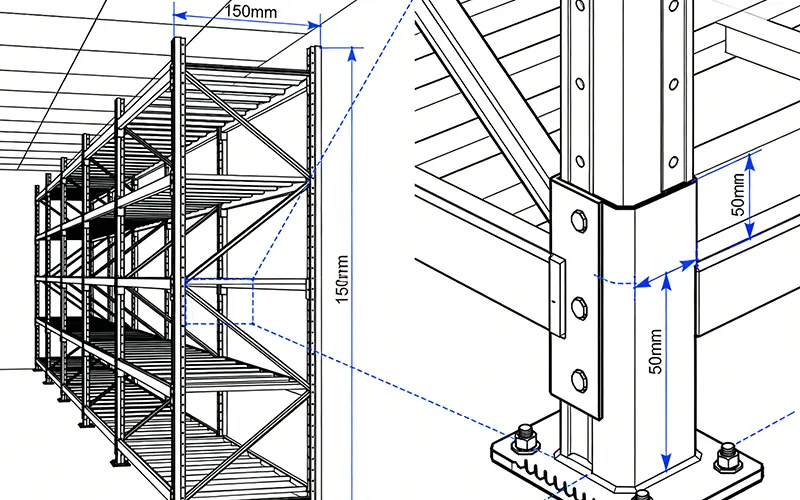

1. Maximizing Every Cubic Centimeter of Space

Custom shelving is designed to fit your facility’s exact dimensions, including unusual ceiling heights, pillar placements, or room shapes. We engineer systems that utilize 95%+ of your available space, creating denser, more organized storage.

2. Built for Your Specific Inventory

Do you store long metal bars, fragile glass panels, heavy engine parts, or small electronic components? We design shelf depths, heights, load capacities, and accessory integrations (bin dividers, drawer units, foam padding) specifically for what you store. This minimizes damage and maximizes organization.

3. Integrating Seamlessly with Workflow

We design the storage system to complement your process. This can mean creating a dedicated “kitting” area with integrated workbenches, designing mobile tool carts that dock into shelving units, or establishing a logical pick-path sequence that halves walking time for your team.

Our Collaborative Process: From Your Idea to Your Floor

- Consultation: We discuss your needs, challenges, and vision.

- Analysis & Planning: We assess your space and inventory data.

- Custom Design Proposal: We provide tailored layout diagrams and product specifications.

- Collaborative Refinement: We work with you to fine-tune every detail.

- Precision Manufacturing & Delivery: We build your solution with quality materials and deliver it ready for implementation.

The Bottom-Line Impact

Investing in a custom storage solution translates to measurable business outcomes:

- Increase Storage Capacity by up to 40% within the same footprint.

- Boost Picking & Retrieval Efficiency by 30% or more.

- Enhance Workplace Safety and reduce product damage.

- Improve Employee Morale with an organized, efficient environment.

- Achieve Faster ROI through significant gains in daily productivity.

Ready to Build the Solution Your Operation Deserves?

Stop trying to make standard fit. Elevate your storage from a necessary cost to a strategic asset.

Contact us today for a free, no-obligation consultation. Send us your floor plans or simply describe your challenge. Let’s design a storage system that works as hard as you do.

Email: info@zdlhtools.com

WhatsApp: +86 15806555955

Learn more about our approach:Contact – zdlhtools.com